Computer-aided manufacturing (CAM) is a tool or program that numeric control (NC) to create detailed instructions the drive CNC machines. Cam software prepares a drawing for production, which considered the last step of the design process. It checks the geometrical errors. It gives the coordinates that the machine is required to follow during the process. It automates the device’s parameters, which makes the machine operators’ job simplified. CAM software will send all the required information to the CNC machine. It allows high-speed machine tool paths, provides functions to improve production efficiency and reduce waste.

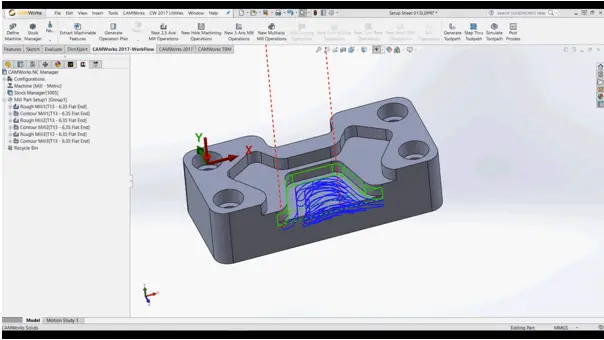

1. CAMWorks

CAMWorks is a CNC software that provides aid for manufacturing machine tools. Integrate CAMWorkswith other software like SolidWorks, which makes it fully integrated. It eliminates time to make changes to your design in this software. This advanced programming software allows you to manufacture products faster and at a low cost. The associative feature of this software will enable you to update changes made in design into machining operations. Its automatic feature recognition allows you to reduce complex programming hours by interpreting the design of parts. Increase productivity by using automation tools to maximize machining efficiency. Users can now program smartly to get work done efficiently.

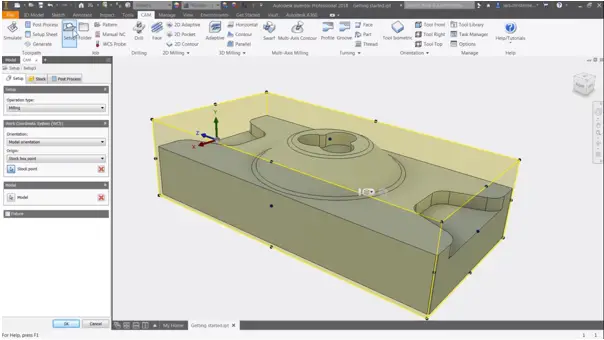

2. Autodesk HSMWorks

Integrate HSMWorkswith CAD easily. Work in an interface that is easy to use. Powerful design tools are available to make changes to your design. Maximize production with 2.5 and 3-axis milling. Use Multi-axis programming to tighten feature tolerances. It allows shortens the time taken for setting up the machine. Preview your machine tool with simulation to see how it works program turning operations from 2-axis to mill-turn strategies. Reduce cycle time for creating your design. Simply design and generate your CAM tool without changing software. Use HSMXpress plug-in for other features like 2D roughing and pocketing.

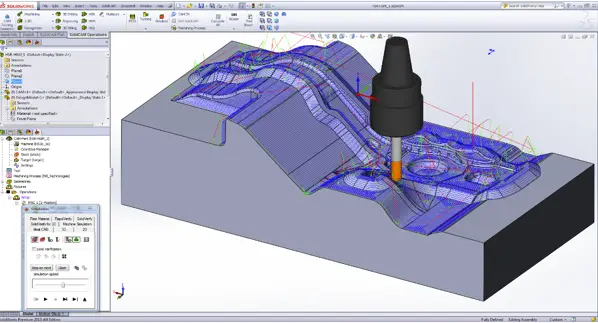

3. SolidWorks CAM

SolidWorks is easy to learn the software with powerful functionality. It shortens product development time. Reduce costs in manufacturing and improve the quality of your product. The 3D design will let you validate your product and transform your ideas into products. Use your images to make animations using this software. Visualize your products in virtual reality. Make simulations to analyze the physical behavior of your product. Virtually test your CAD models. Improve the quality of your product and reduce the cost that you spend for making live prototypes. Use specific tools to simplify electrical product design. Manage your data files to maximize productivity. Securely store your data design and collaborate designs in multiple locations.

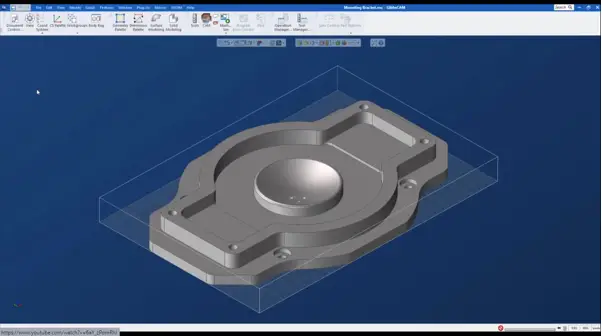

4. GibbsCAM 3D systems

Use this as a CAM software solution for any CNC machine. Its interface is easy to use and customizable. It is specially designed for CNC programming. This error-free software will give you the best designs. Get accurate simulation from this software. Perform machine simulation for most complex machines too. Use its multi-tasking machining programming capabilities to aid you in designing. It uses an advanced approach for tool movement. Various cutting strategies are available in this software. Its face milling capabilities has new features. New turning productivity tools are available. Use the linear and rotary functions as new broaching functions. Streamline the user experience with this software.

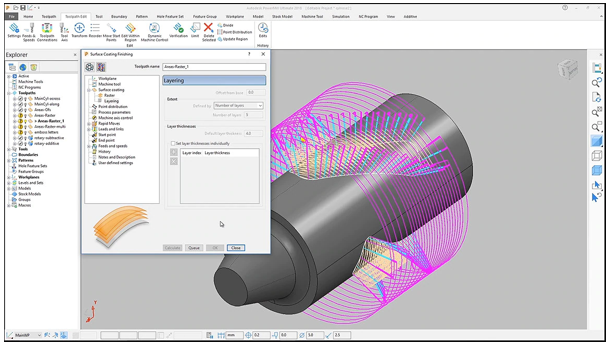

5. PowerMill

Perform 3-axis and 5-axis programming smoothly with Powermill. Perform simulation of design to verify the output of the product. Calculate Tool paths quickly for complex machine parts. Use high-efficiency roughing to cut pieces faster. It increases tool life and reduces the cost of maintenance. Improve surface finishing using the tools available. Continuous 5-axis machining will allow challenging parts of the design to be machined safely. Use automatic tool axis tilting to simplify the process of creating collision-free tool-paths. Automatic orientation vectors improve the synchronization of the simulation. Get specialized solutions for industries like electrode manufacturing. Analyze leftover material using the stock analysis feature. Automated verification is available to verify collisions in your CAM project.

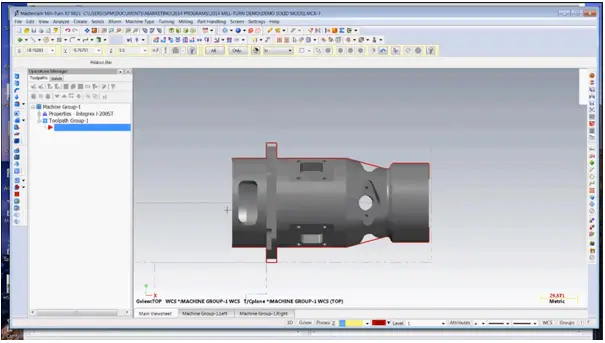

6. Mastercam

Mastercam uses powerful tools for speedy performance. Many in-depth features are available in this software to complete complicated jobs. Remarkable tools make work efficient for you. Connect with the largest CAM community all over the world. Use leading-edge features for precision. Use special Add-Ons like Prodrill, Blade Expert, Port Expert, and many more for specific machining needs. Integrate Mastercam with other software like DNC Solutions and Post Processor Solutions. Reduce the cost greatly and get efficient results. Visualize data to find all errors and correct them before actual production.

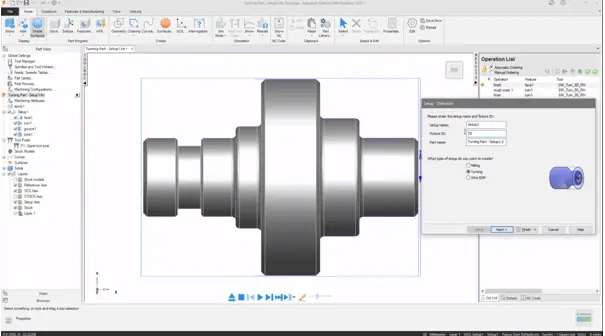

7. FeatureCAM

Make decisions intelligently using manufacturing knowledge in this CNC programming software. Remove repetitive processes to produce the best results. Manufacturers standardize the quality of the product to promote repeatability between employees that use the setup. Use a single interface for all CNC applications. Visualize programming with simulation tools. Cut bottlenecks in your program and make your design effective. 5-axis toolpath in FeatureCAM reduces machine setups. Feature recognitions enable programming to be faster. Reduce costs with high-efficiency tools. Use Bar-fed mills to combine continuous part production capabilities. Use collision avoidance to trim toolpaths. Use work holding devices like clamps and fixtures to avoid work in certain parts of the design.

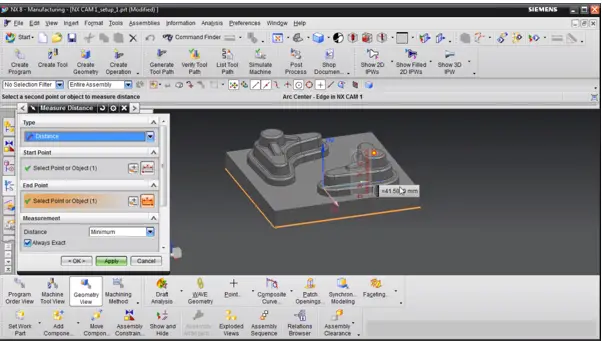

8. NX CAM

NX for manufacturing makes manufacturing efficient. It delivers high-precision parts through digitalization. Control robotic cells using this software. Control 3D printers using this software to make your product. Transform your product to a digital form first to increase profitability by reducing costs. Use additive manufacturing to create revolutionary products. Reduce cycle time with this CAM software. Use powerful Computer-Aided Design tools to form digital parts of the model. Validate the quality of the product using digitalization. Save time and reduce errors. Accelerate production with multiple setup machining.

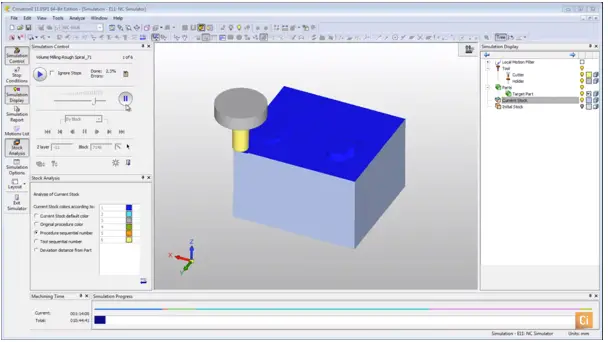

9. Cimatron

Climatron is a single integrated solution tool. It boosts productivity and handles any geometry. Machine any part of design through this software. Get local training and support from tooling experts. Make molds and manufacture electrodes. Start your work with any input geometry. Shorten tool delivery time and deliver a high-quality surface. Easily handle changes using this software. Conformal cooling is a new feature that accelerates the productivity of your design. Simply import your data and create designs. It makes electrode designing and CNC programming easy. Customize your workflow to manufacture your products.

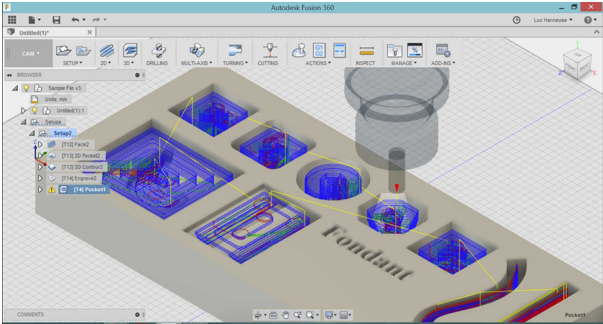

10. Fusion 360

Fusion 360 allows you to collaborate on 3D designs with anyone inside or outside the organization. With Fusion 360, users can view and work with 3D models-anytime, anywhere, as it is a cloud-based software. It supports more than 100 formats, including DWG, SLDPRT, IPT, IAM, CATPART, IGES, STEPS, STI, making it easy, simple, user-friendly to share designs with the team, clients, partners, and friends. Users can view and track project activities and updates, access design properties, and complete parts lists. It has features to isolate and hide components in the model for easy viewing, and the user has access to review large and small 3D designs and assemblies.