Electrical discharge machining (EDM) is a manufacturing procedure that carries out electrical energies to construct a metal shape. Because of these sparks, EDM is also occasionally cited as spark machining. In this process, the desired pattern is trimmed from the metal when current combustions, or sparks, arise between two electrodes; where the sparking occurs, cuts are made into the metal, building the desired shape and separating it from the metal sheet.

Two fundamental types of EDM are wire and sinker. Wire EDM utilizes a wire as the equipment electrode. The wire is gash between two spools and when in action, the strong part of the wire frequently switches, deterring the equipment from deteriorating from the wire itself. Wire EDM machines can carefully eliminate additional substance without wielding a strong reducing force. The procedure is often automated, implying it has a limited opportunity of inflicting destruction to the workpiece itself. And because wire EDM machines can adapt hard substances, there is no need for secondary, post-machining thermal treatments. As a result, there is slight to no heat pressure positioned on the shaped part, and a slight possibility that the texture of the part will become contorted.

The top 10 Wire EDM machines latest are:

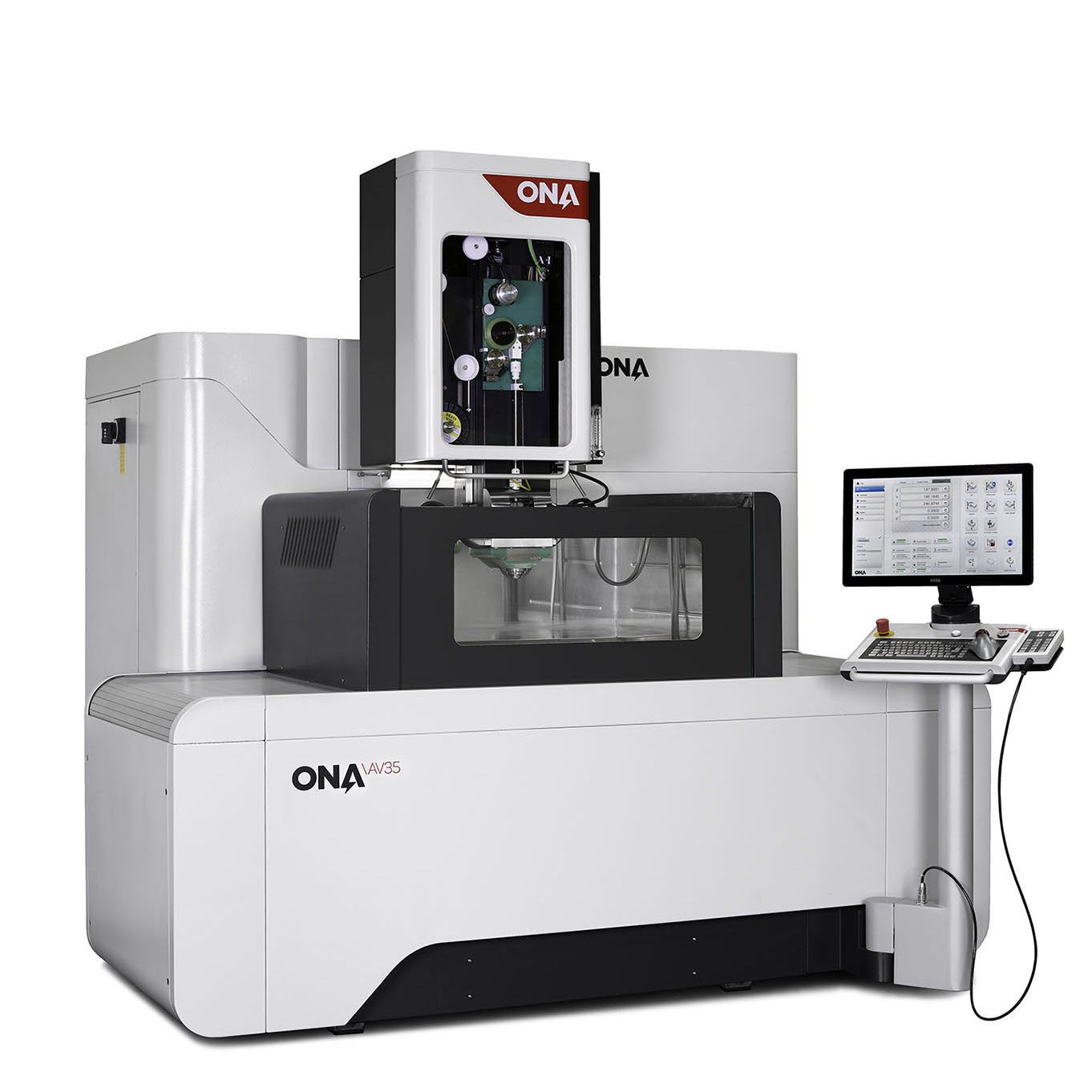

1. ONA

ONA is a Spanish brand and it has a very restricted orientation to the USA market. Their opening was large work appliances and also some aerospace. Plus, it was very difficult to get assistance because you could not maintain track of who was the distributor of the brand in the USA. According to LinkedIn, they are the most ancient EDM machine manufacturer in the world.

2. Brother WEDM

Brother WEDM is a very fundamental two Axis and four Axis work that is considerable for a Garage Shop or starter WEDM. However, assistance is difficult to find these days in the USA.

3. ACCUTEX and EXECTEK

ACCUTEX and EXECTEK are a lower price choice and seem to be copies of the other categories and do not provide high precision work. They do appear to be enhancing the systems.

4. Mitsubishi

Mitsubishi is one of the oldest non-linear machines and is much better than ball screw era machines. It arrives from the understanding of assistance techs wanting to do a ball bar examination and establish parameters to get the WEDM to cut around dowel holes. This was performed on new appliances on every set-up. The rigidity of the old machines is not up to the mark. New Linear machines appear much more stringent and have an adequate design, fitting the e-pack technology that was always reasonable and appeared to make the appliances so prominent. The Linear motors have made the formation more stringent than the old ball screw standards per an enterprise specialist as it is rectifying the structure errors in the layout of the machine.

5. Fanuc

Fanuc is a very popular EDM machine and the users like the appliance and they operate it much longer than you would anticipate. It is considerable for improvement and widespread WEDM jobs. The assistance is also certainly promising as well.

6. Sodick

Sodick appliances are prepared with in-house formulated NC supervisions, linear engines, and action buttons. They have generated with their proprietary linear motor drive operations forty-five thousand units trucked worldwide. The industry’s only ten-year placing precision guarantee has now verified itself for twenty full years since its beginning. Sodick altered the industry of appliance devices worldwide with linear motion. Their cutting situations were a vulnerable point in the past. Technology in the appliances is good as well.

7. Seibu

Seibu elevated accuracy wire EDMs are hundred percent made in Japan. They are the only EDM manufacturer who safeguards a grade precision down to +/- 1 micron. They established the world’s initial CNC wire EDM in 1972. Their wire EDMs are built-in Seibu’s ISO authorized plant in Koga City, Fukuoka Prefecture which is located in southern Japan. Seibu appliances target the high-end accuracy wire EDM market which compels a quality machine formulated to last and generate consistent outcomes for twenty-five-plus years. Only fifty machines are separately handcrafted per month. Seibu’s generating ideology is about quality and not quantity. All machine castings are hand-scraped, which utilizes an edge to eliminate high spots left behind during the machining procedure occurring in enhanced part geometry, repeatability, and texture finish. Guideways are scanned for flatness, flashes for straightness, and test slices are accomplished on all appliances which are tested on a CMM for precision. Since Seibu wire EDMs are generated in Japan, they are created for accuracy and will survive and exceed the competition.

8. Makino

Makino is a world administrator in technology and WEDM is no oddity. They have thrived from an opening machine to an influential performer in the industry. Their WEDM appliances are created just like their milling devices. With more than one hundred and forty patents, a Makino EDM implies quickly processing times and improved texture finishes for even the most sophisticated part geometries. Makino swivels creation and technology into raised creation and a lesser cost per part for their customers.

9. Charmilles

Charmilles commenced the EDM business in 1952 in Switzerland, making the first appliance in 1955 in Milan Italy. Their supervisors were easier to comprehend but still influential. They made numerous examples during those two decades. They had a high precision model and a high taper model, both tremendous appliances in their respective applications.

10. Agie

Agie has been the world leader for many years, they are the most detailed WEDM in the market and everyone was hustling about them for many years. The supervision was the hardest to comprehend and the number of pages that were utilized to operate the machine was much more than any of the others.