Nanoscale materials and devices, those engineered at dimensions under 100 nanometers, empower transformative applications across industries. Manipulating matter at the atomic level unlocks astounding potential to enhance products through remarkably precise control of fundamental properties. As research continues probing nanoscale frontiers, promising innovations steadily materialize into commercial implementations. This article spotlights IT applications already harnessing nanotech’s versatility to push boundaries. Spanning sectors from microelectronics to medicine, select examples warrant attention for overcoming limitations through ingenious nano-engineering. Touchscreens gain durability and responsiveness via nanowire components. Composite spacecraft parts resist weathering from unfiltered sunlight. Tumor-hunting nanoparticles ferry targeted drug payloads. Connected wearables monitor sweat composition. Though nano-enabled upgrades sound fantastical, constant improvements across research facilities and fab labs ensure more formerly fictional ideas morph into commonplace conveniences.

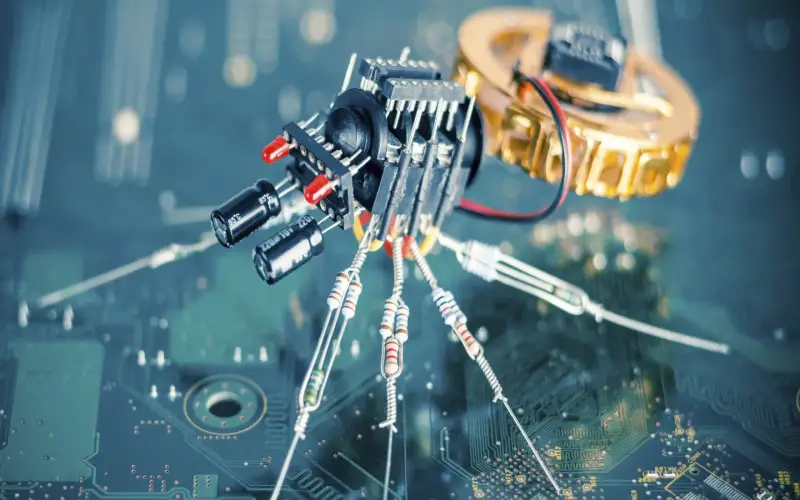

1. Nanotech In Electronics

At the electronics’ heart, transistors switch between conductive and resistive to shepherd flows of data. Though silicon suffices for most needs, nanotubes and nanowires unlock faster, efficient computing by providing extra control over electrons’ movement. Their minute size also enables packing more components onto tinier chips. Companies like IBM already implemented carbon nanotube development for next-gen processors and RAM. While costs currently limit mass production, nanoelectronics keeps improving telecommunication and computing speeds as devices shrink.

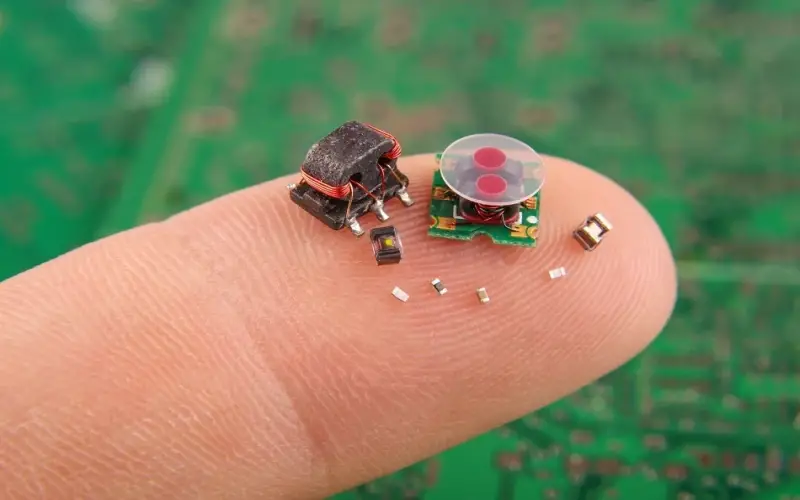

2. Sensors

Nano-enhanced sensors reliably detect minute chemical signatures and temperature shifts imperceptible to traditional monitors. Arrays of nanotubes and nanowires calibrated to identify specific molecules aid homeland security, public health programs, and industrial facilities by sniffing out vapors from explosives, toxins, or leaks. These sensors’ sensitivity and selectivity outperform conventional options. Meanwhile stretching or compressing certain nanomaterials changes their conductivity proportionally to applied force; integrating such components measures stresses or pressures. Advanced sensing supports infrastructure longevity, prompt emergency response, and human safety.

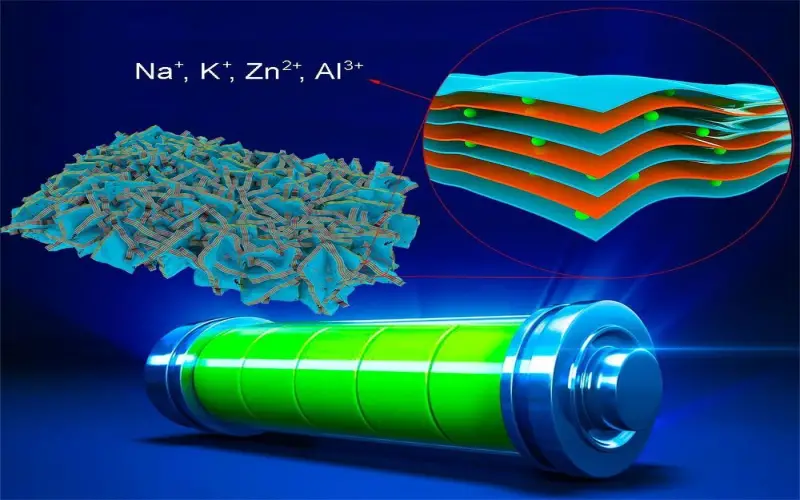

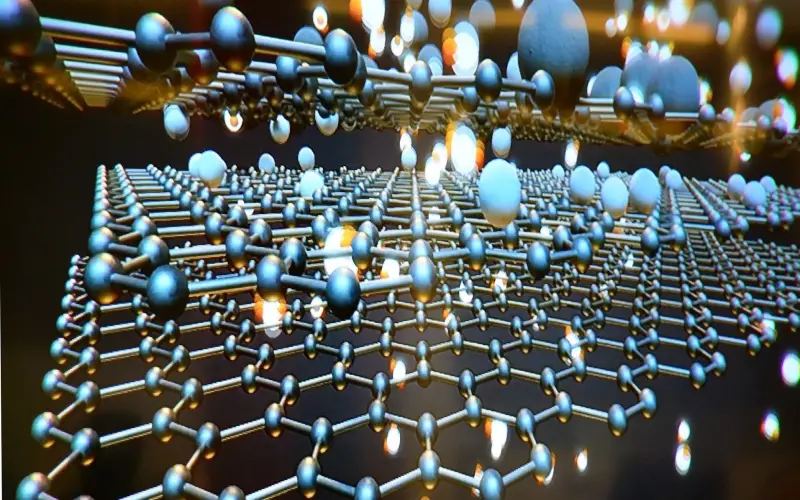

3. Energy Storage

Superior surface area within properly structured nanomaterials benefits batteries and supercapacitors by giving more locations for storing and discharging power. Layers of graphene or tiny titanium oxide tubes recharge rapidly. Controlling nanoscale features during manufacturing maximizes storage capacity. Durable lightweight nano-enabled devices better equip eco-friendly electrics and portables. Startups even envision micro batteries that safely integrate directly inside networks. More efficient nimble energy storage assists in transitioning away from fossil fuels.

4. Thermoelectric Materials

Thermoelectric nanomaterials convert waste heat into recoverable electricity via the Seebeck effect. They also pump heat for temperature regulation. Nanoscale engineering judiciously sculpts chemical and physical properties to optimize conduction. Then alternating n- and p-type legs leverage charge flows across temperature differentials for generating electricity even from subtle heat differentials. Integrated heating/cooling systems shrink. More programs now recover waste heat from power plants, engines, and factories. Versatile durable thermoelectric modules made using nanotubes, nanostructured silicon germanium, and other nano-engineered materials maximize energy utilization.

5. Tires

Incorporating lightweight silica nanoparticles into synthetic rubber improves tire performance and fuel efficiency. The silica particles’ small size enhances grip, strength, and durability by increasing binding sites across the rubber matrix. Reinforcing tires this way allows the designing of higher-performing profiles. Suppliers add nanoclays for further enhancements. With proper dispersion protocols and safety testing, nanofilled tires last longer, saving resources. Nanotech also enables embedded sensors to monitor temperature, pressure, and tread wear. Smart tires increase automation and optimize functioning.

6. Fuel Additives

Precisely synthesized cerium oxide nanocrystals blended into diesel and biodiesel fuels catalyze more thorough combustion helping engines run cleaner. Platinum nanoparticles serve similarly. Better burning means more miles per gallon, fewer emissions, and reduced leftover contaminants gumming up systems. Treatments improve efficiency. Cerium also scrubs corrosion from storage tanks. Nanoscale catalysts enable cleaner transportation with minimal added costs.

7. Food Processing

Engineered nanomaterials deliver antimicrobial silver nanoparticles protecting perishables from microbes during shipping. Curcumin nanoformulations enhance flavor and longevity across foods from sweets to grains. Iron oxide nanoparticles manage moisture during storage protecting grains fit for aid distributions. Silicate nanoparticles even filter waste fertilizers for recycling. Targeted nano interventions reduce waste in production pipelines. The smart moderate application ensures safe optimization.

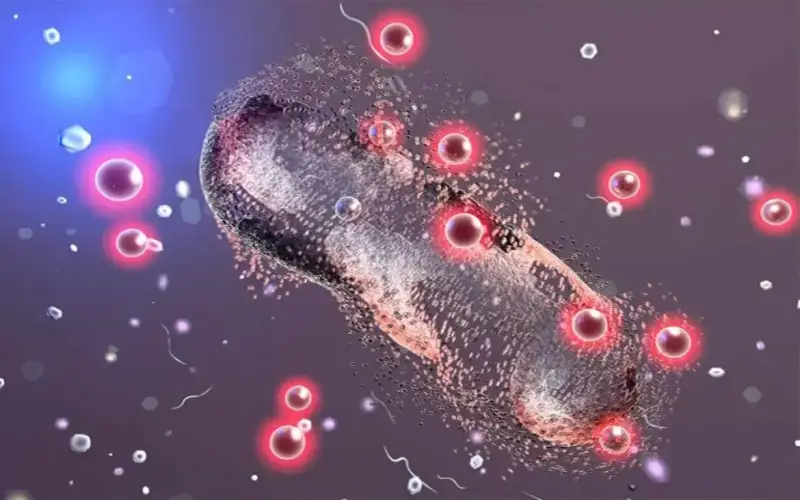

8. Drug Delivery

Liposomes and dendrimers fabricated from engineered nanorods expertly ferry titrated drug payloads toward pathological sites. Nanoparticle carriers adorned with targeting chemical groups accumulate preferentially around lesions and tumors before releasing medicines directly into cells. This improves efficacy allowing lower doses and mitigating complications from systemic exposure. Further bioengineering removes residues after drug delivery preventing accumulation. Well-designed targeted nanoparticles greatly assist precision medicine.

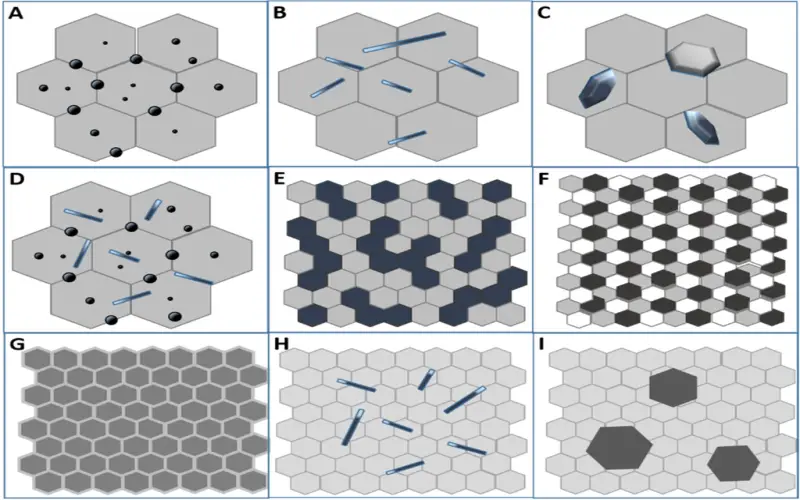

9. Composite Materials

Nanofillers like graphene flakes or nanocellulose fibrils bolster the strength and durability of everyday items from clothing, sports gear, and luggage to vehicle parts and wind turbines. Reinforcing polymers, metals, or ceramics this way utilizes abundant sustainable materials with smaller processing footprints compared to alternatives. Customizability options also abound. Engineers directly tune composite characteristics by adjusting nanofiller shapes, sizes, orientations, and defect densities for needed lightness, conductivity, insulation, or reactivity. Multiscale modeling predicts optimal combinations.

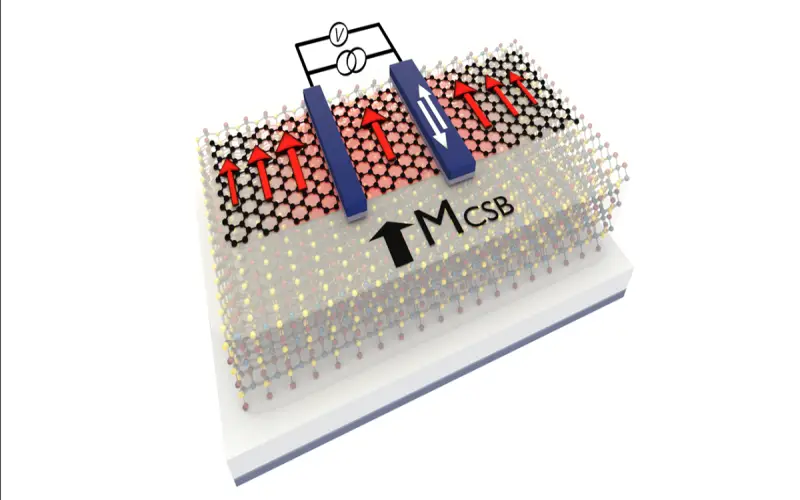

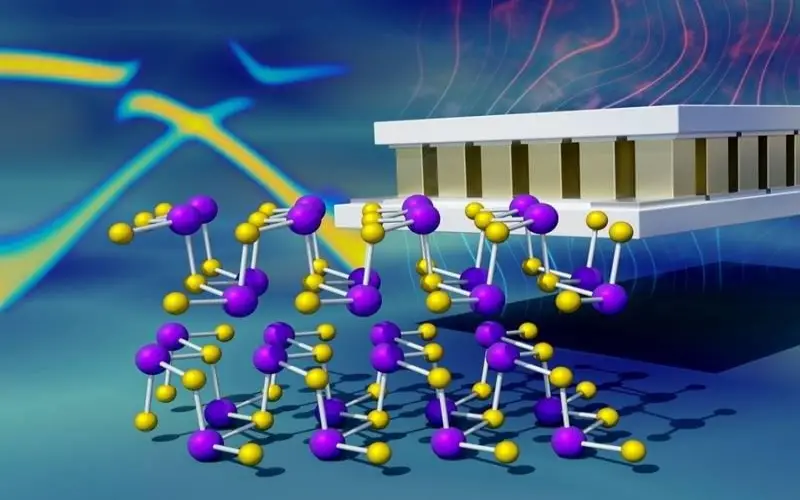

10. Spintronic Devices

Conventional electronics harness charge flow, while emerging spintronic devices additionally leverage electron spin for improved memory, sensors, and quantum computing. Spin transport depends sensitively on atomic structure. Nanotechnology provides the meticulous engineering capability essential for operational spintronic components. Magnets narrower than 100 nanometers sustain single domains to polarization akin to giant atoms. Their stability empowers spin-based logic gates. Devices even reconfigure magnetic domains on demand for multifunctionality. While challenges remain, spintronics progress toward enabling powerful low-energy computing.