Smart factories also known as Industry 4.0 have revolutionized the traditional manufacturing processes by incorporating advanced technologies. A smart factory is an industrial setup that integrates AI, IIOT(Industrial Internet of Things), robotics, and automation to enhance the manufacturing process. It is an advanced industrial facility that enables easy exchange of data through a network of connected machines, devices, and manufacturing systems.

Today, smart factories have emerged as a decisive element in driving growth and innovation in modern industry.

Manufacturers in smart factories utilize smart sensors and other IoT-enabled devices to streamline the manufacturing process. Mobile robots are utilizes to automate the manufacturing process. The robots work alongside human workers to help improve overall operational efficiency and performance. Smart manufacturing focuses on minimizing cost, and save time and labor expenses. Smart factories incorporates IoT platform to automate the production process. Utilizing internet-based technologies enables data analysts and engineers to analyze machines and equipment and identify any faults or defects in the machine.

Modern machines can detect problems in real-time with the help of built-in remote sensors and diagnostic solutions.

Smart factories oversee each production activity including supply chain management, equipment, and individual operators in the factory shop. Smart factories have experienced rapid growth in recent years due to their capability to streamline complex processes and reduce human errors caused by inefficiencies. The benefits of utilizing smart manufacturing are:

- Enhanced efficiency

- Improved productivity

- Reduction in manufacturing costs

- Better quality control

- Reduced downtime

In this article, you will learn about the top 10 smart factories in the world.

1. Siemens

Siemens is a German company offering a diverse range of electronic devices such as washing machines, refrigerators, ovens, etc. Siemens incorporates smart manufacturing technologies inti its production processes. The company has also incorporated 3D printing technology as a part of its manufacturing strategy. Siemens is focused on developing supply chains, smart buildings, healthcare, and sustainable transport system worldwide. The company utilizes Industry X solutions to drive advanced automation and digitalization across its manufacturing processes.

2. Bosch

Bosch is a leading engineering company in Germany, famous for rendering smart manufacturing solutions. The company offers services in various sectors, including construction, consumer goods, energy, and industrial technology. Bosch incorporates advanced technologies such as IIoT and connectivity to create a unique combination of machines, devices, and systems within the factory. Industrial robots and automation streamlines the production process within the company. Bosch has optimized almost all its production and logistics processes by incorporating Industry 4.0 solutions.

3. Honeywell

Honeywell is a US company with headquarters in North Carolina. The company offers advanced industrial automation solutions to improve efficiency in the manufacturing process. The company provides customized IIoT solutions, enabling easy data transfer across manufacturing systems. Manufacturers can quickly analyze data in real time and optimize manufacturing processes using company’s latest sensor and software tools. Honeywell focuses on achieving sustainability and operational efficiency through continuous development and innovation.

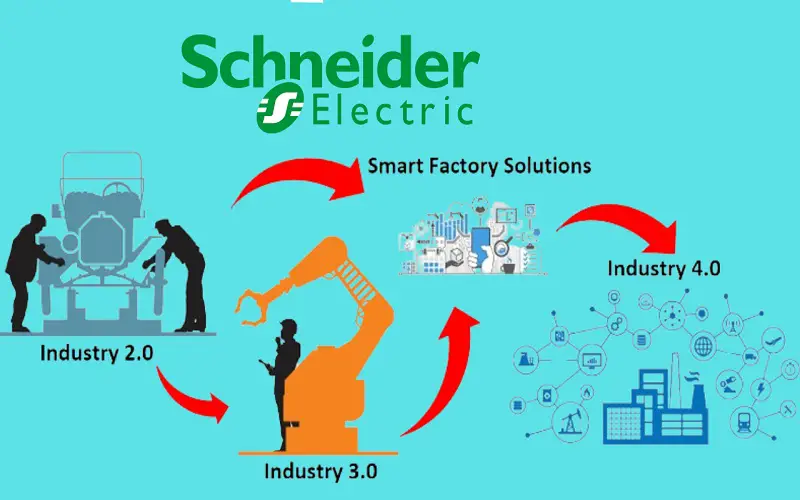

4. Schneider Electric

Schneider Electric, a French multinational company, is a global leader in the smart manufacturing industry. Their prime objective is to achieve energy efficiency and sustainability. The MNC offers various services to manage energy consumption and facilitate automation. Schneider provides advanced industrial automation software and products, including user-friendly control panels, automated machinery, robotics, and more. The company utilizes digital twin technology to develop virtual models of physical processes.

5. Mitsubishi

Mitsubishi is a leading supplier of electronics and electrical equipment. The company’s headquarters is in Tokyo, Japan. The Japanese MNC offers a range of factory automation solutions integrating robotics, control systems, and software. Its advanced IoT-based platform collects the data from various sensors and offers real-time monitoring and predictive maintenance services. Mitsubishi leverages the power of IoT and edge computing to enable data-driven decision-making and improved connectivity.

6. Fanuc Corporation

Fanuc Corporation is a Japanese company that manufactures CNC systems and industrial robots globally. Its smart manufacturing solutions focus on automating the manufacturing processes. Fanuc’s cobots(a unique combination of articulated, delta, and collaborative robots) help in increasing the speed and flexibility of industrial operations. The company also incorporates digital twin technology to create a virtual replica of its physical manufacturing systems.

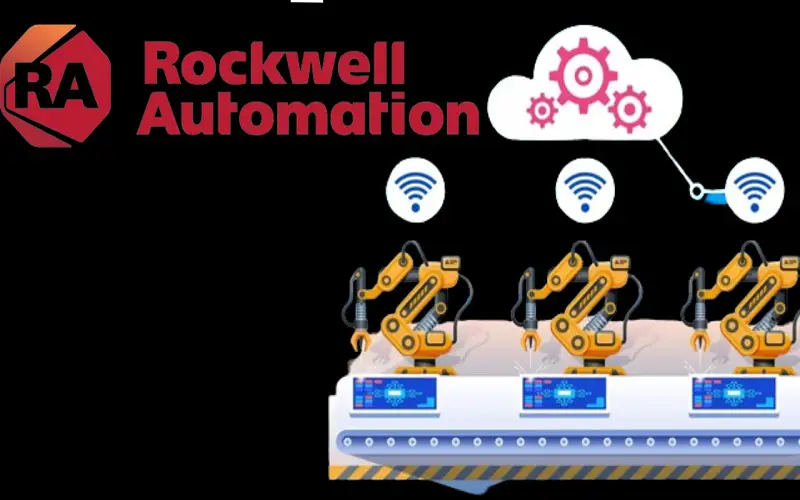

7. Rockwell Automation

Rockwell Automation is an US company that provides industrial automation and information services to streamline the production processes. The US-based company utilizes IIoT and edge computing to analyze data from industrial devices. Rockwell’s smart devices provide real-time information about your machine’s performance and status. The company leverages advanced automation technology to enhance its lifecycle management processes and protect against cyber attacks. Rockwell considers data from machines and sensors to be significant components of the smart factory.

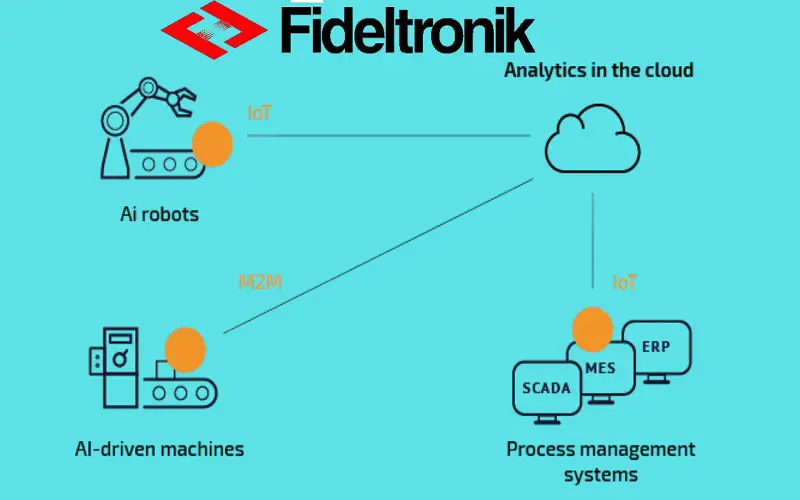

8. Fideltronik

Fideltronik is a leading company known for offering services ranging from innovative designs to rapid prototyping and after-sales services. The company’s headquarters is in Poland. The company provides services of rapid prototyping, bulk manufacturing, creation of innovative designs, and after-sales services. Fideltronik employs AI technology and data analytics to create an innovative workspace for highly sought-after projects.

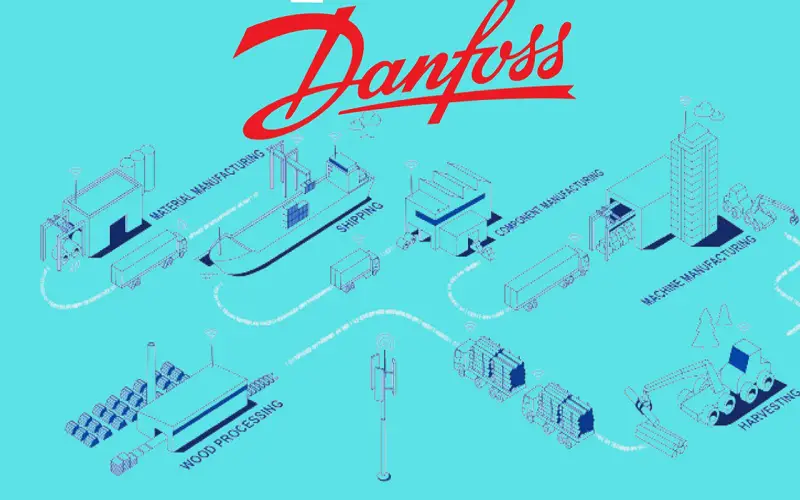

9. Danfoss

Danfoss is a Denmark-based MNC offering intelligent and energy-efficient solutions to achieve environmental sustainability. The company offers automation, software, and sensors to streamline the manufacturing processes. Danfoss regularly invests in research and development to identify and track latest technologies. By integrating automation and connectivity, Danfoss focuses on developing high-end products with reduced environmental effects.

10. ABB

ABB is a leading tech company with a global presence, headquartered in Zurich, Switzerland. The company designs and manufactures electrical equipment, including circuit breakers, sensors, and power converters. ABB focuses on achieving a sustainable future by utilizing robotics, automation, electrification, and industrial technology. Within ABB’s smart factory, industrial robots work collaboratively with human workforce to complete high-demanding projects. The company’s smart manufacturing solutions ensure optimized energy consumption, reduced wastage, and enhanced productivity.