What Is Industrial Remote Connectivity?

It refers to remote access to connected industrial machines where you can distantly troubleshoot and program programmable logic (PLCs), view and handle Human-machine interfaces (HMIs), and merge to an IP camera for support field with specific difficulties. About per cent of performing problems faced by industrial machine manufactures, original equipment manufacturers (OEMs) and constructing companies can be resolved by industrial remote connectivity to a machine’s control system. It is facilitating both machine manufacturers and building companies.

How Does Industrial Remote Connectivity Work?

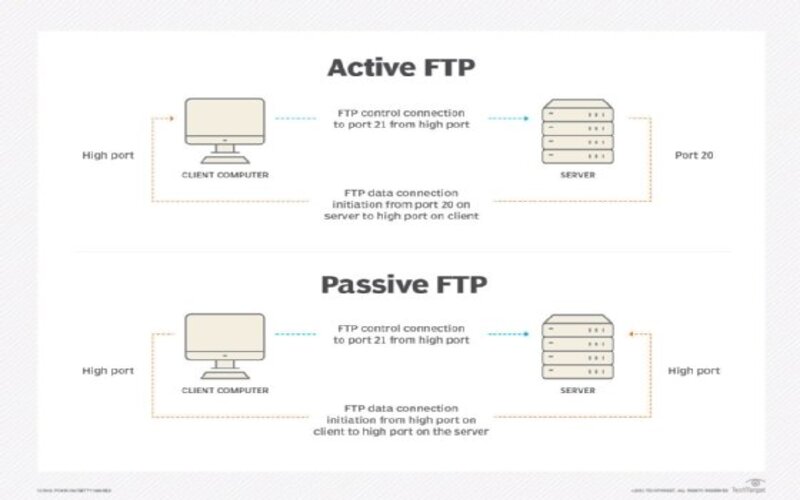

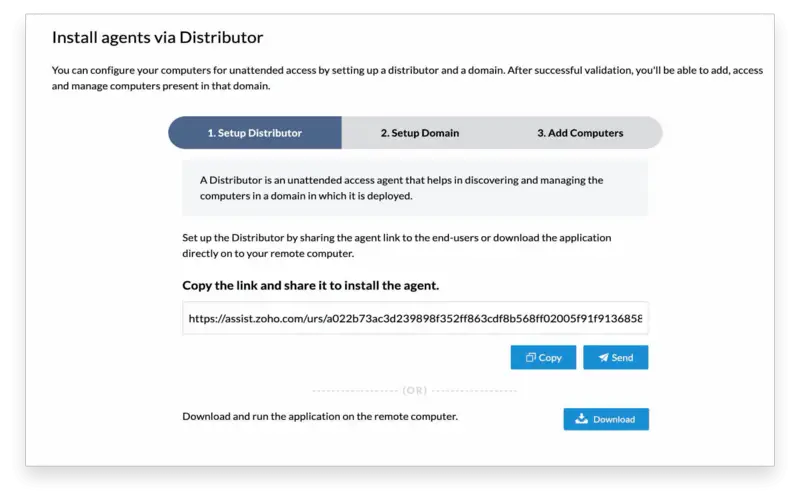

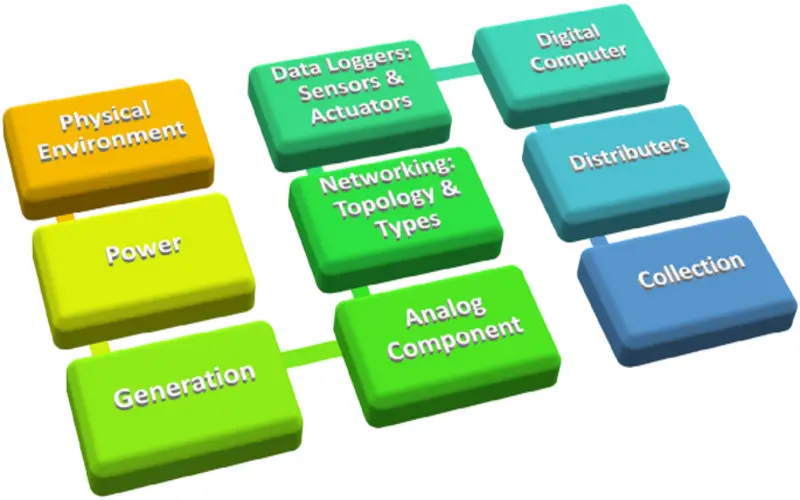

The primary principle to manufacturers’ successful industrial remote connectivity to any appliances depends on two main parts:

- One general idea of cloud connectivity services is to coordinate all aspects of connectivity.

- A hardware gateway is positioned inside the handle panel of the appliances and merged to control devices such as PLCs and HMIs.

Why Is Industrial Connectivity Required?

Industrial connectivity is required to allow machines on the field stage to send procedure data to industrial automation handle systems, such as Programmable Logic Controllers (PLCs) or Programmable Automation Controllers (PACs), on the handle stage. Businesses can then use the data to automate procedures or send the data to personalized dashboards or higher-stage systems such as SCADA, MES, or ERP for beyond evaluations.

What Are The Advantages Of Remote Connectivity?

As management worldwide has quickly extended remote work, they have described enhancements in overall productivity and employee experience. With a highly mobile workforce, remote connectivity allows companies’ operations to move forward no matter where staff are located or when they want to work. As remote work has grown more common, businesses can reduce their sustainable office space, saving significant money on rent or real estate investment.

Benefits Of Industrial Connectivity

- Enhanced performance with more significant energy savings.

- Have the most modern connectivity accessible that works well with other devices.

- Using appliances suited to your business requires needs to exposure more excellent and reliability.

- Have the latest machines up and running quicker for greater productivity.

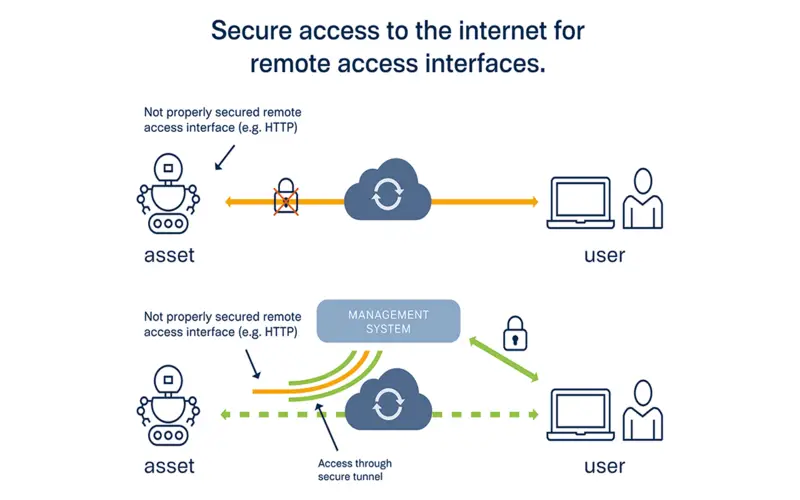

- Have maximized security as machines are patterned to meet the newest safety traditions.

- Minimizes risks and costs and having the latest software and hardware lets you have updated innovations that will receive upgrades to keep your company present. It may be costly at first but less extravagant overall.

- Have greater visibility into working to understand your company’s performance Better.

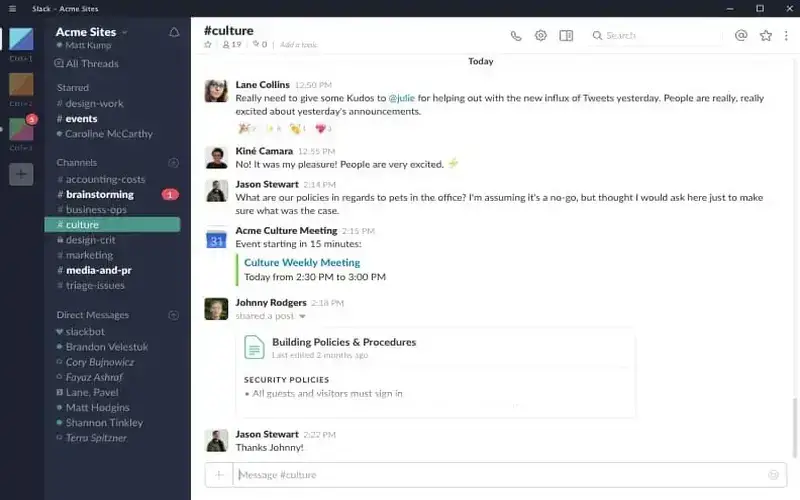

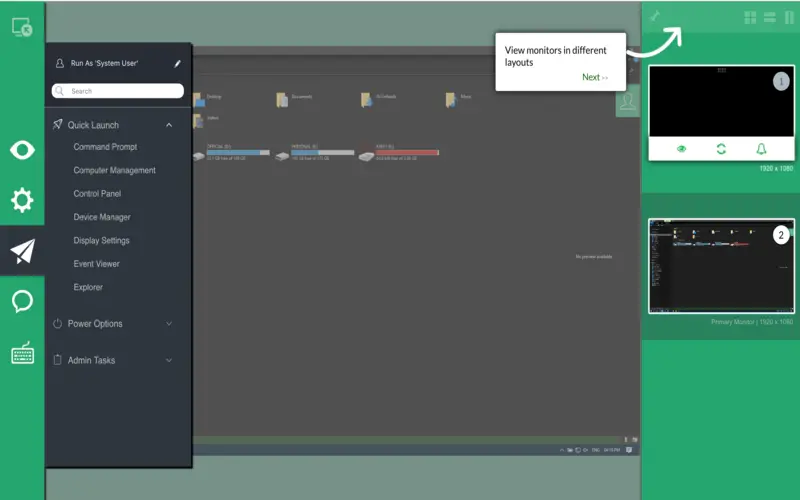

1. Two-way Desktop Sharing

Two-way Desktop Sharing enables a consumer to share their screen with a user, coworker, or remote support technician. It also allows them to share screens with multiple people at once, such as when giving a presentation to different clients. It facilitates and accelerates the combination process and can be helpful in a wide variety of scenarios.

2. Remote Audio

The ability to allow audio enables the consumer to hear sound from the remote computer. Remote audio can be helpful in video editing, which enables the user to listen to sound distinctly, as they are working at their computer. Consumers can frequently adjust remote audio to meet their particular needs, turning it off as needed.

3. File Transform

File Transform enables a consumer to quickly remove files if a consumer wants to replace a corrupted or irrelevant file. It can be helpful if a consumer transforms files from a monitor to another device. It can relieve the procedures because the consumer no longer has to depend wholly on external tools such as email communication.

4. Remote Printing

Remote printing enables a consumer to send documents reserved on a remote device to a device to be printed. Rather than transforming and downloading the file to the local device, it’s instantly connected to the printer. This feature can effectively save time by easing the printing procedures for the consumer.

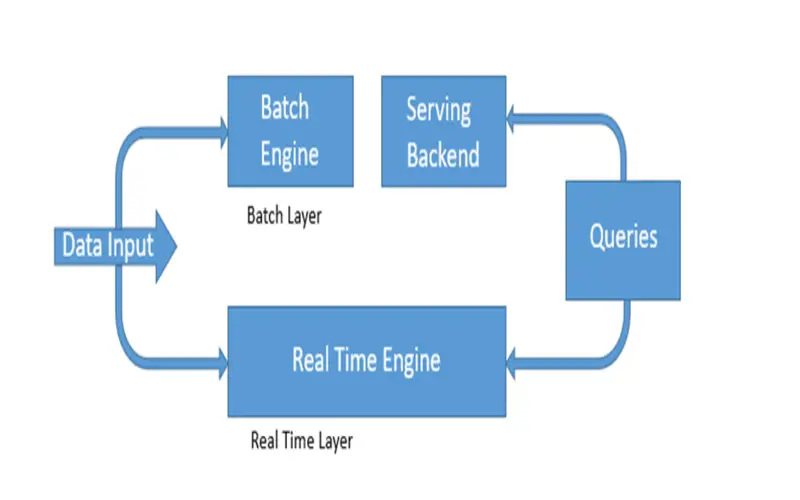

5. Actual -time Data Conveying

Remote industrial connectivity benefits the actual time conveying of data between devices, sensors, and control systems. The ability to ensure decision-makers have access to updated information, enabling them to respond immediately to changing situations and evaluate operations.

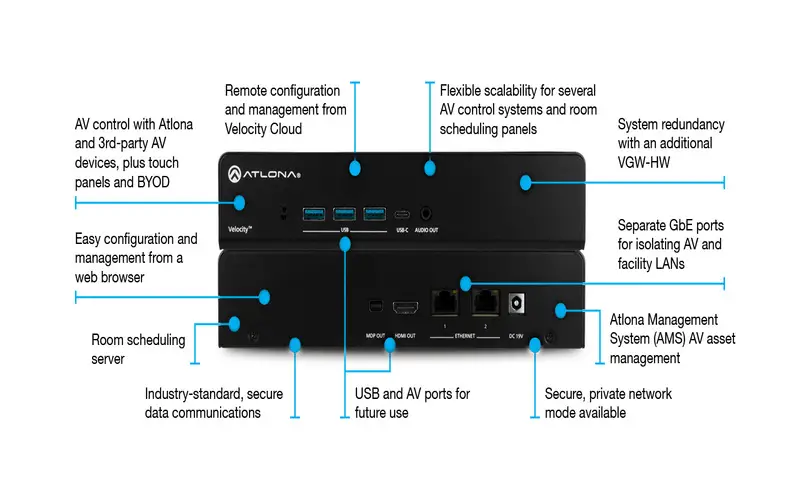

6. Scalability And Reliability

A robust remote connectivity solution should be scalable to assimilate the growing number of connected devices and reliable enough to modify to changes in the industrial environment. This scalability allows businesses to enlarge their operations without serving the existing connectivity structure.

7. Security Controls

Security is supreme in industrial settings. Remote industrial connectivity features robust security controls to secure sensitive data, avoid unauthorized access, and reduce potential cyber threats. Encryption, undenied, and access protocols are efficient parts of a secure connectivity framework.

8. Flexible And Redundancy

Industrial procedures demand high levels of flexibility. Remote connectivity answers include redundancy phenomena to ensure continuous operation, even in the features of network failures or appliance malfunctions. Redundant collaboration ways and failover phenomena distribute to system resilience.

9. Remote Observing And Diagnostics

One of the primary advantages of remote industrial connectivity is the capacity to observe appliances and processes remotely. It involves actual-time diagnostics, predictive support, and troubleshooting, enhancing overall appliance effectiveness (OEE) and minimizing downtime.

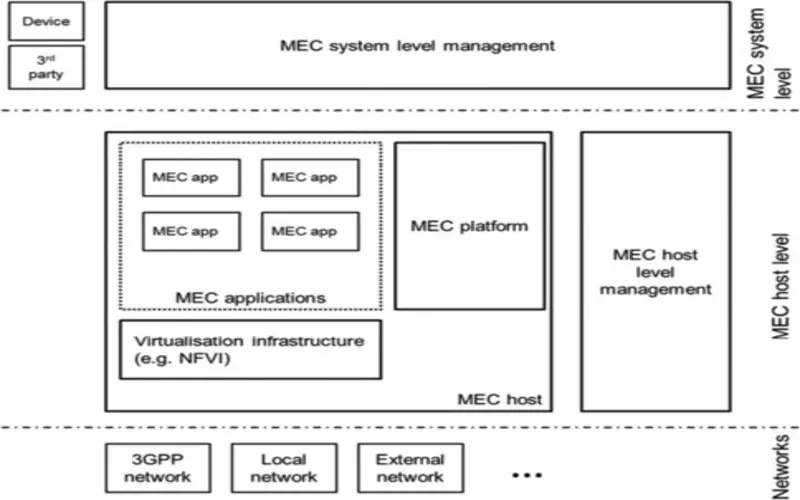

10. Edge Computing Abilities

Remote industrial connectivity frequently uses edge computing to proceed data closer to the source. It minimizes latency, reduces bandwidth needs, and allows faster decision-making at the network’s edge. Edge computing is singly costly in applications where actual time responses are crucial.