The evaluation of printing started with the evaluation of human civilization. The earliest form of printing recorded in China during 220 AD. The advanced mode of printing with technology involvement started around the fifteenth century by Johannes Gutenberg. Since the journey of evolution continued with invention of various forms of printing like letterpress, offset, silk screen etc. However, the modern era revolutionized the printing world by invention of digital printing, which is faster, safer and more efficient requires less set up and running cost. Since digital printing came into the picture, the scope of printing technology has widened and the research started as early as 1980’s to identify methods of additive manufacturing or creating three dimensional objects from any digital shapes. The research continues for some decade and eventually in the year 2010, 3D (Three Dimensional) printer first makes its commercial entry into the world of manufacturers and consumers.

So far, the concept of printing was limited to two dimensions only where the content could be printed on various substances including paper, plastic and even foils. The whole concept of 3D printing lies to the contrary in the present form of printing, which restricts itself into two dimensions. With the expansion of industrial design, aerospace, civil, medical, biotech, automotive, etc. the need for different mode of representation or quicker prototyping started getting its momentum.

Till now, the availability and affordability of 3D printers compared to conventional ones are much limited and restricted. However, the growth projection is evident and the future seems to be bright. The 2012 market survey revealed $2.2 billion worldwide business for the 3D printers, which is around 29% jump from 2011 figures. The figures reflect and stiff growth trajectory for this 3D printer market and associated services.

The technology that is used in 3D printers like fused filament fabrication (FFM) where a plastic filament first melted and then deposited on a smooth surface or print bed. The print bed is gradually lowered and layers of deposition eventually create a 3 dimensional object. Most of such printers use substances like Acrylonitrile Butadiene Styrene or Polylactic Acid type of plastic as input as they melt easily. However, as the day passes, we are observing an increase in the trend of using exotic materials as input like clay, plasticine and even chocolate.

1. MendelMax

The best way to learn is to learn using self help techniques. This printer eventually can be used by anyone. The plans can be downloaded and parts can be purchased from the Web. In case you fail to find your required part then don’t worry, several companies are available who offers parts at a reasonable price. The cost of the printer is also reasonable come at approximately $ 1.5K. Everything you can build using the 3D printer is available to you in a package. This is one of the fastest printers in its category and can print large models with a print area ranging 12.4 x 9.4 x 8.8 inches. Periodical updates are also available from the manufacturer at a reasonable price.

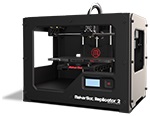

2. MakerBot Replicator 2

MakerBot, one of the first commercial 3D printer manufacturers created its Replicator 2 model at a price of around $2K. This is considered to be groundbreaking invention from the company. It’s a powerful printer and can print large areas covering 11.2 x 6 x 6 inches. At the same point of time this printer is simple to use, easy to set up and comes with a software package which can handle the processing of 3D computer models and a very fast speed. Various upgrade alternatives are provided to the consumers like dual print heads, which supports more than one material or colors. Replicator 2 offers you a good value for money for those wants to make a quick and easy printing at ease.

3. Stratasys Mojo

This printer is primarily targeted small businesses who use a 3D printer for daily use and look for something very reliable with good technical support. There is no doubt that although this is costlier at $ 10K (approx) but the company provides outstanding technical support to small business enterprise that uses their product. The Mojo as an input material uses ABS Plus thermoplastic, which can be used for making complex and larger objects. The printer also has inbuilt washing facility.

4. RoboX 3D Printer

This is a printer from CEL UK. It uses plastic filament as input and can print using a couple of different shaped nozzles. Although this is targeted towards the commercial users, but the price bracket of approx 1.3K can attract general home users as well. The RoboX can be used for quick printing of parts that are primarily internal type and are not externally visible. The printing happens precisely with delicate details on the print surface. It offers a promising future in the 3D printer market.

5. Pegasus Touch Printer

This printer uses STL for printing and is quite expensive. It uses bit complex technology, which makes it costly. The possibilities are there that a future version could see a price cut owing to the advancement in technology. This printer uses a spectrum laser to cut the input material and provide desired shape. The cost is around $3.3K which is expensive compared to its siblings. The printer is feature rich and can cover a print area as wide as 7 X 7 X 9 inches. It also has a built in a Linux-based computer system that controls the entire printing process and it does not require any separate computer as such. It also offers touch screen features to its users.

6. The Engine

The Engine is manufactured by Hydrel. If your objective is to print using very unique materials such as clay, rubber, Nylon etc., then you can trust on the Engine. It has got an open built space and can print a maximum size as 8 x 8 x 8 inches. It uses an embedded computer and touch screen display to facilitate operation at a cost of around $2.1K.

7. Bukito

Like its name, it is a tiny small printer and easily portable with a weight less than 2 KG. It can even print on the go and even when used upside down. Because of its small size, the objects it can print are smaller in nature with a maximum print size of 125 x 150 x 125mm. It uses print resolution of around 50 microns for standard axis and 100 micron for the third axis. It supports various objects as input like Nylon, PLA and ABS and cost just around $ 600. This 3D printer is very affordable one for the home users.

8. Kevvox

Kevvox conventionally targets commercial buyers who can afford to shed $17K for meeting their 3D printing needs. However, this printer is considered for its highest precision and quality output. It comes with integrated software module which can create an entire printing workflow starting from design to extrusion and quite easy to handle and manage.

9. Doodler

Doodler is considered to be one of the coolest gadgets as it offers to 3D printing functionality in the form of a pen. You can load the device with a color of your liking and start drawing. During printing it places plastic on the printing bed.

10. Xfab

The Xfab uses a printing process known as stereolithography and uses an ultraviolet laser that helps to harden a light-sensitive material to create 3D output. It is a highly precise device which can focus the laser with accuracy during the printing operation. It is of course better than printers using extrusion-style for printing.

3D printing is going to be a key industry in 2014 and will empower both makers and users. Customization is going to be the next buzz word in3D printing technology and days are not far when People will be able to do various things at their home at a very low cost. 3D printing is surely going to completely revolutionize the manufacturing world as we know it.