Vehicle technologies are growing at a vast pace nowadays. Ships and navigation of our country have always been in a respectful and also in a very responsible manner. The appearances it may be minor but the technologies and the minute parts of the vehicle are to be seen from its making. This way, let us look at the top ten techs used by engineers and professional inside a ship.

1. LNG FUEL FOR PROPULSION

LNG is a well-known ship technology for fuel saving. When LNG fuel is added to diesel oil, the air pollution can be reducible. Moreover, the performance of the engine will be doubling. LNG fuel is an expectation to be the best technology for the future.

2. DIGITAL SENSORING

The technology of sensor is useful in the ships for maintaining the performance, operations, and even detecting the fault in areas inside the vehicle. With the association of this technology, even the powerful ships can be controlled and communicated by the land-based team persons.

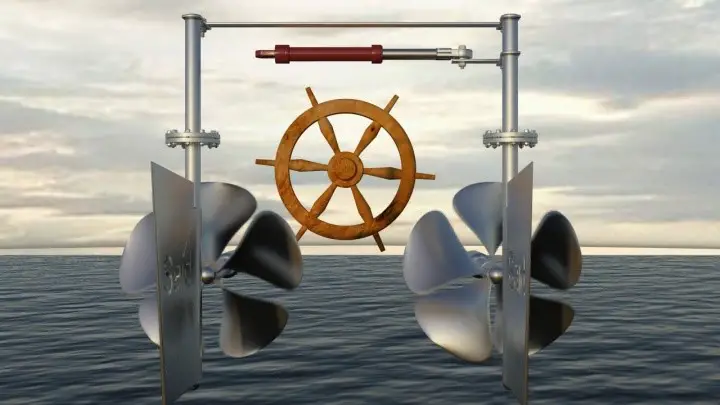

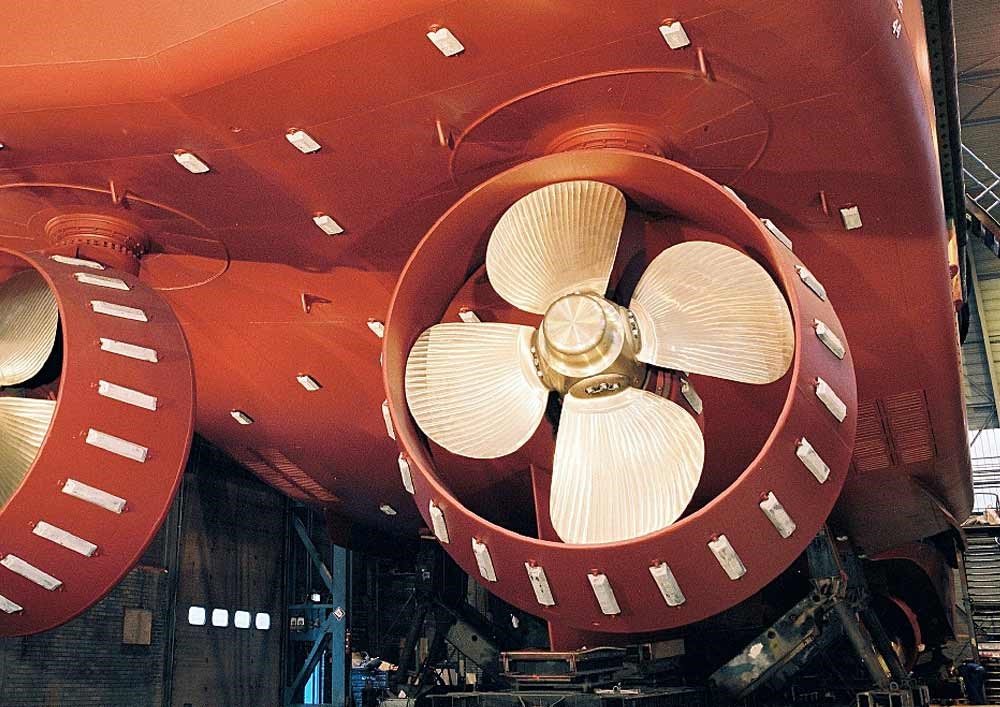

3. ADVANCED RUDDER AND PROPELLER SYSTEM

Rudder and propeller system is a well-designed technology for ships for reducing the consumption of fuel up to four percent less than its emission. The propeller system will also be helpful in the working conditions of the vessel during high speeds.

4. SOLAR AND WIND POWER FOR SHIPS

Solar and wind power technologies are useful for so many commercial shipping procedures. The solar and wind power is an energy saving method particularity for the marine industry. Some of this technology has been tested and trialed. The Turanor Planet consists of more than 29,000 thousands of solar cells which is a supplement for fuel.

5. SPEED NOZZLE

The Speed Nozzle has been developed for small merchant vessels to improve the efficiency in functions of propulsion by saving the power up to 5%.

6. BIGGER MEGASHIPS

The larger mega ship technology was for updating to the container shipping industry. The MOL Triumph is the world’s largest container ship which was finished 2018-March. This 400m long ship will carry up to 20,150 TEU containers.

7. WATER IN FUEL

Water also with fuel will reduce the rise of temperature inside the ship’s cylinder. The rise of this technology will be resulting in the reduction of nitrogen monoxide up to 30-35%.

8. PUMP AND COOLING WATER SYSTEM

Generally, the loss of heat energy will affect the ship’s engine during its long run. The problem can be avoidable by the cooling technology useful for the machines inside the marine. There are two types of cooling systems- the Sea Water cooling system and the fresh water cooling system. These systems save up to 20% of electric power and about 1.5% of the total fuel consumption.

9. WASTE HEAT RECOVERY SYSTEM

The waste heat recovery system is widely useful nowadays as it powerfully reduces the fuel’s consumption by 14% and being more effective in use. The exhaustion of the gases from waste heat produces heat and generates steam which can be useful for the cargo ships.

10. HULL PAINT

By applying the appropriate paint in the exact outer layer of the ship could help in reducing the frictional resistance by 3-8% for its fuel savings. Thus, the emission will improve the general life for the outer layer of the ship.