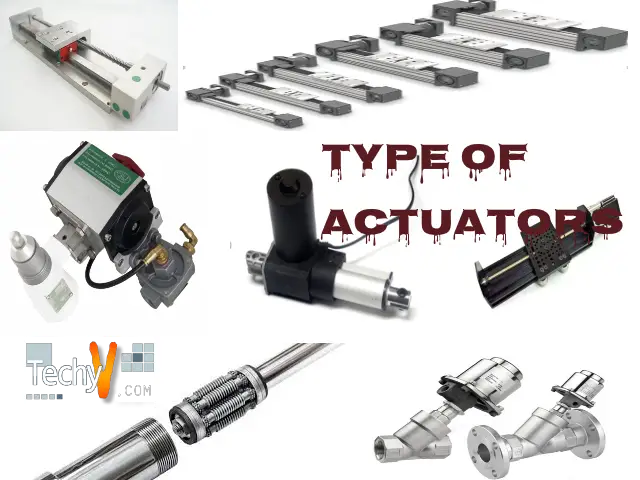

Almost half of our engines and machine run and move with the capacity provided by the mover, the actuator. We nowadays have so many types of new actuators that are under manufacturing in industries. Thus, we will discuss the 10 common but useful type of actuators.

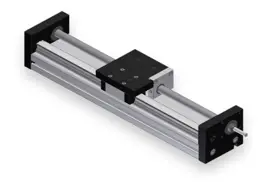

1. SCREW TYPE: The most peculiarly and a highly customized design option is the variety of screw type linear actuator. The mechanism has a nut that rotates and it moves along with an inbuilt screw shaft. Moreover, there are various versions of the thread type which provides the regular and subsequent breakdown for most of the mechanisms.

The most peculiarly and a highly customized design option is the variety of screw type linear actuator. The mechanism has a nut that rotates and it moves along with an inbuilt screw shaft. Moreover, there are various versions of the thread type which provides the regular and subsequent breakdown for most of the mechanisms.

2. BELT DRIVES: The most cost-effective type of actuator is the belt drives. Having a relatively simple design for its structure, the belt drives are very beneficial with its high maintenance. The only con is its vulnerability to stretch in its core element.

The most cost-effective type of actuator is the belt drives. Having a relatively simple design for its structure, the belt drives are very beneficial with its high maintenance. The only con is its vulnerability to stretch in its core element.

3. ROD TYPE: Rod type actuators are the ones that have its core scheme with a thin wall tube which is metallic the presence of a thread. The tube acts as a pull-push function for a machine. The power is thus generated with the rotation of the pipe with energy via the screw gear.

Rod type actuators are the ones that have its core scheme with a thin wall tube which is metallic the presence of a thread. The tube acts as a pull-push function for a machine. The power is thus generated with the rotation of the pipe with energy via the screw gear.

4. DIRECT DRIVES: The primary con here is that due to the interlinking availability there is a significant loss in the power supply for the engine or mechanism. Still, it is useful by excluding the intermediate which is present in home applicants like a fan and a washing machine.

The primary con here is that due to the interlinking availability there is a significant loss in the power supply for the engine or mechanism. Still, it is useful by excluding the intermediate which is present in home applicants like a fan and a washing machine.

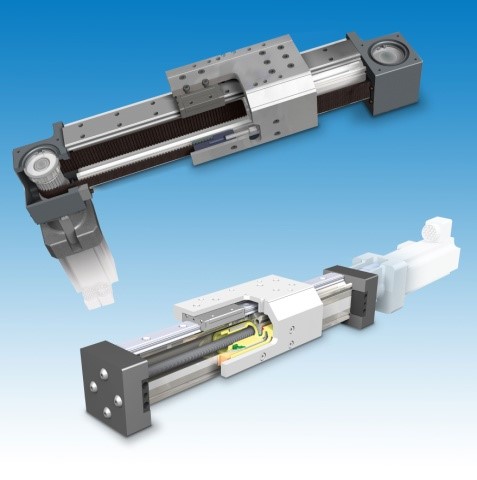

5. BALL SCREWS:

When you replace a screw with the help of a ball bearing (s) becomes a ball screw type of actuator. The design comes handy when an application requires high accuracy in its movements.

6. LEAD SCREW: Lead screw actuators have a screw in their design. The on-ward motion or friction is producible when the screw rotates. But there are chances of high loss of frictional energy.

Lead screw actuators have a screw in their design. The on-ward motion or friction is producible when the screw rotates. But there are chances of high loss of frictional energy.

7. ROD AND ROD-LESS STYLE:

The only difference in both these actuators lies in the fact that the rod type functions for pulling and pushing activities whereas the rod-less style will move along the pathway of a carriage.

8. GEARED DRIVES: As the name states, geared drives are actuators that produce energy through the power produced in the rotation of a gear. The principle works the same as a wheeled engine or a gear for a vehicle produces energy. The products are strictly take-off and intake shafts.

As the name states, geared drives are actuators that produce energy through the power produced in the rotation of a gear. The principle works the same as a wheeled engine or a gear for a vehicle produces energy. The products are strictly take-off and intake shafts.

9. PLANETARY ROLLER SCREW: The biggest positive of the planetary roller screw form actuator is that it gives only a minimal level of loss of power. But due to its highly complicated design, it is a bit costly for purchase.

The biggest positive of the planetary roller screw form actuator is that it gives only a minimal level of loss of power. But due to its highly complicated design, it is a bit costly for purchase.

10. PNEUMATIC TYPE: A pneumatic type of actuator functions by transforming or converting the device’s energy into a full form of mechanical energy. With the type of another actuator the movement is liner or rotational, also depending on the mechanism.

A pneumatic type of actuator functions by transforming or converting the device’s energy into a full form of mechanical energy. With the type of another actuator the movement is liner or rotational, also depending on the mechanism.